How AI Technology Is Redefining the Manufacturing Workforce

AI Technology Is Redefining the Manufacturing Workforce

Artificial Intelligence technology has become significant in automating and smoothing out the whole manufacturing ecosystem, from routine decisions to official level decisions. Many people across the world are wonder if manufacturing organizations could depend on the machines and remove human jobs.

Even if the topic is emotionally charged, manufacturing managers can use the facts to determine how AI and other digital disruptive technologies can be used in the business. To be competitive with other manufacturing companies, manufacturers need to accelerate with transformation and not let the fear of the unknown hinder progress. While it may sound intimidating, Artificial Intelligence in manufacturing is also exciting, and it doesn’t go away.

Source: Markets and Markets

AI Applications in Manufacturing Industry

Let’s continue reading to know where AI is being applied in the manufacturing sector and how AI works in manufacturing.

i) Personal Assistants for the workplace

One of the crucial and existing applications of AI in the manufacturing industry is the Personal Assistant for the workforce that communicates with the customer, solve queries, perform duties, and offer some recommendations, etc. by using Natural Language Processing.

ii) Facial recognition:

This facial recognition became known at first when the largest social media platform, Facebook started ‘recognizing’ human faces to tag. In the manufacturing industry, AI applications can be used for visual confirmation of quality control and security clearance. For example, if the potato chips are dumped into the packaging with only red jelly beans or the right golden, this AI works well and will identify you in the audience.

iii) Fraud detection:

Banks use AI to determine when there are ‘atypical’ charges against your account, which triggers a fraud alert. Manufacturers can monitor identical anomalies to flag customer orders outside of normal patterns, which can indicate defects. It can also be used to monitor compliance with regulations and security orders.

iv) Predictive Maintenance Analytics

Administrators can find very accurate predictions by using Artificial Intelligence built-in BI solutions. It increases the knowledge base, identifies patterns, and find out the effect and cause relationships. In addition, data can facilitate in improving the forecasted output and accuracy.

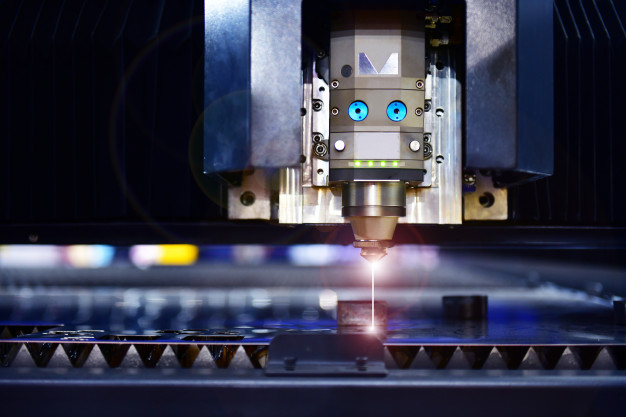

v) Automation

Many routine tasks in a manufacturing plant will be automated with the trending AI. Workflows will be established, enabling data points to be reflective of, reports generated, signal notices, re-orders placing, reserve parts, flag issues for review, dispatch staff, and schedules updating.

Also Recommended to Read: Use Cases of AI in Manufacturing

The Present State of AI Technology

Many industry scholars agree that AI has a big impact on all businesses, especially the manufacturing sector. IT service management company, Gartner said that by 2020, the number of users of advanced analytics platforms would be differentiated by increased data discovery capabilities, which will double the rate and double the business value”.

AI is embedded in several technologies, from networked supply chains using predictive analytics to ERP solutions with built-in-BI capabilities.

In a thought to give you a clear idea, here we are taking a reputed manufacturing company as an example, which has introduced AI to redefine manufacturing analytics.

Sight Machine Launched AI to Redefine Manufacturing Analytics

Sight Machine, a manufacturing Analytics Company, located in San Francisco, aims to disrupt the manufacturing industry by offering an Artificial intelligence-based manufacturing analytics platform that collects, improves and inspects information to acquire actionable insights and real-time visibility.

The company’s Factory TX platform provides manufacturers with the adaptability to obtain the data of machine from the cloud and production facilities. Their tool allows for quick deployment and centralized management of multiple industrial facility IoT data intake. Insights are generated in real-time and integrate device data, process quality data, and product data with installed Enterprise Resource Planning data and handled to produce important insights using Machine Learning and AI.

Benefits of Using AI in Sight Machine

The main advantage of AI in manufacturing is that it makes digital twin resources as well as procedures. Using AI, the plant management will track man, machine, material, and also process that drives ceaseless process development. In addition, this platform helps in combining data from several manufacturers, historians, Enterprise Resource Planning, and other machines. Moreover, this platform helps improve quality, reduce time, increase the utilization of capacity, reduce scrap, measures and improves OEE and productivity, etc.

Artificial Intelligence will also play an important role in helping humans do their jobs. AI is just a tool, but not a replacement, for improving business insight and decision-making.

Impact of AI technology in Workforce

The term AI enables workers to visualize the future, where machines run themselves and robots are gradually welded and bolted to parts without human attention. As a large number of smart manufacturing companies grows, humans are still playing an important role in operations, and this is likely to continue for decades.

These false assumptions can lead to improvements and advanced applications. Employees may assume that AI technology coverts to reductions in the count of human jobs. Engineers, data scientists, and other technicians may mistakenly assume that the profession in manufacturing is short-lived and will soon be replaced by technology. Such fears could prevent the next generation of skilled professionals from even considering employment in the manufacturing industry.

Recommended to Read: The Revolution of AI Technology

The lack of skilled professionals in manufacturing is one of the main concerns of industry; About 426,000 Manufacturing jobs in the USA are not filled because there are not enough skilled applicants to obtain those. Yet, 80% of companies lack the workforce needed to implement AI projects.

Therefore, a mystery is created. As skilled workers are in a dilemma that AI technology will eliminate jobs, they might not applied for vacant positions. But the lack of skilled employees makes it tough to implement those sophisticated technologies.

There is a high demand for employees who are skilled in AI technology, but hiring candidates is not so simple. Hence, A few manufacturers are giving training to them to develop internal AI expertise. One of the practical ways to gain experience is turning to software providers and third-party resources.

Final Words

Leveraging new and trending technologies and updating processes like AI technology and Machine Learning are keys to remaining competitive and relevant in the manufacturing industry. Artificial Intelligence is one of the most effective and powerful platform that manufacturers can adopt. As Manufacturing firms need to focus on the future with utmost confidence, they will make active decisions.

If you are also planning to take advantage of Artificial Intelligence for your manufacturing company, contact us.

Our USM AI Professionals will provide you complete information.